Industrial automation has changed the way factories work, but robotics has taken this change to a whole new level. Today, robots are no longer limited to big automobile plants. They are now used across industries such as electronics, food processing, pharmaceuticals, logistics, and even small manufacturing units. Robotics in industrial automation is not about replacing humans—it is about working alongside them to make production safer, faster, and more reliable.

At Techy Hussain, we believe robotics is the backbone of modern smart manufacturing. Let’s explore how industrial robots are used and the real benefits they bring to industries.

Understanding Robotics in Industrial Automation

Robotics in industrial automation refers to the use of programmable machines (robots) that can perform tasks automatically with high precision and consistency. These robots are controlled using PLCs, sensors, software, and sometimes AI-based systems. Unlike traditional machines, robots can adapt to different tasks, making them flexible and efficient.

Industrial robots can work 24/7, handle heavy loads, and perform repetitive tasks without getting tired. This makes them ideal for environments where accuracy, speed, and safety are critical.

Key Applications of Robotics in Industries

1. Manufacturing and Assembly Lines

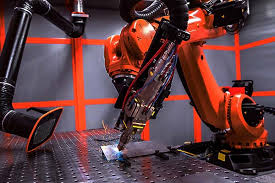

One of the most common applications of robotics is in manufacturing and assembly. Robots are widely used for welding, screwing, fitting, and assembling components. In automobile and electronics industries, robotic arms ensure that each product is assembled with the same quality and precision every time.

Robots reduce human error and help maintain consistent production standards.

2. Material Handling and Packaging

Robots are extensively used for picking, placing, sorting, and packaging products. In warehouses and factories, robotic systems handle raw materials and finished goods efficiently.

This application not only speeds up operations but also reduces the risk of injuries caused by lifting heavy objects.

3. Quality Inspection and Testing

With the help of vision systems and sensors, robots can inspect products for defects that may not be visible to the human eye. They check dimensions, surface finish, alignment, and even color variations.

Automated inspection improves product quality and reduces wastage, which directly saves costs for manufacturers.

4. Painting and Coating

Robotic painting systems are commonly used in automotive and metal industries. These robots apply paint evenly, reduce overspray, and ensure a smooth finish.

This also keeps workers away from harmful fumes and chemicals, improving workplace safety.

5. CNC Machine Tending

Robots are increasingly used to load and unload CNC machines. This application helps factories run machines continuously, even during night shifts, without human supervision.

It increases machine utilization and reduces downtime significantly.

6. Food and Pharmaceutical Industries

In industries where hygiene is critical, robots play a major role. They handle food items, medicines, and packaging in a clean and controlled environment.

Robotics ensures compliance with safety standards while maintaining high production speed.

Benefits of Robotics in Industrial Automation

1. Increased Productivity

Robots work faster and more consistently than humans. They do not take breaks, get tired, or lose focus. This results in higher production output and faster order fulfillment.

Industries using robotics often see a significant boost in overall efficiency.

2. Improved Product Quality

Consistency is one of the biggest advantages of robotics. Each task is performed exactly the same way every time, reducing defects and rework.

Better quality leads to higher customer satisfaction and stronger brand reputation.

3. Enhanced Workplace Safety

Robots take over dangerous and repetitive tasks such as heavy lifting, welding, and chemical handling. This reduces workplace accidents and protects workers from hazardous environments.

A safer workplace also means lower insurance costs and fewer legal issues.

4. Cost Savings in the Long Run

Although the initial investment in robotics may seem high, the long-term savings are significant. Reduced labor costs, lower wastage, fewer errors, and increased production make robotics a cost-effective solution over time.

At Techy Hussain, we often say robotics is an investment, not an expense.

5. Flexibility and Scalability

Modern robots can be reprogrammed to perform different tasks. This makes them suitable for industries that frequently change product designs or production volumes.

As your business grows, robotic systems can easily scale with your requirements.

6. Support for Industry 4.0

Robotics plays a vital role in smart factories and Industry 4.0. When integrated with IoT, AI, and data analytics, robots provide real-time insights, predictive maintenance, and better decision-making.

This digital transformation helps industries stay competitive in a fast-changing market.

The Human Side of Robotics

A common myth is that robots replace jobs. In reality, robotics creates new opportunities. While robots handle repetitive tasks, humans focus on supervision, programming, maintenance, and quality control.

Robotics encourages skill development and opens doors for high-value technical roles. At Techy Hussain, we see robotics as a tool that empowers people, not replaces them.

Conclusion

Robotics in industrial automation is no longer a luxury—it is a necessity for industries that want to grow, compete, and survive in today’s market. From manufacturing and packaging to quality control and safety, robots bring unmatched efficiency and reliability.

As industries move toward smarter and more connected systems, robotics will continue to play a central role. With the right planning and implementation, businesses can achieve higher productivity, better quality, and a safer work environment.

Techy Hussain believes the future of industry is automated, intelligent, and human-centric—and robotics is leading the way.

Expert support. For quick assistance or product inquiries, call 99116 45145 or visit https://techyhussain.com/ to explore the complete range online.